Stihl MS 400 C-M

Designed for the most demanding tree care and forestry professionals, the STIHL MS 400 C-M is built with STIHL M-Tronic™ engine technology to deliver low-emission, fuel-efficient performance even under changing conditions. Unlike its aluminum piston-equipped counterparts, the advanced magnesium piston in the MS 400 C-M provides greater displacement, power and torque without additional weight. A long-life HD2 air filter means you simply clean it instead of replacing it, while a pre-separation system removes large debris before it even gets to the air filter, increasing run time between cleanings.

|

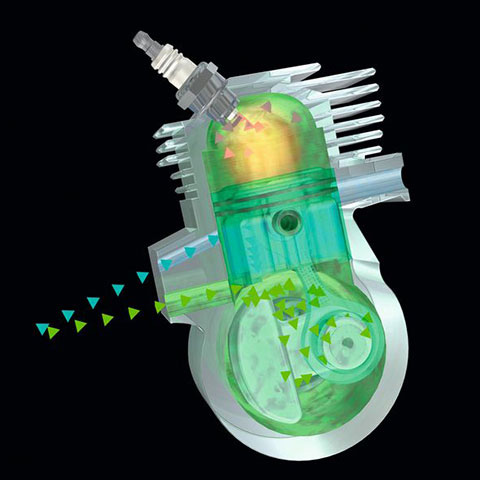

Fully electronic controlled ignition timing and fuel metering system. The engine management STIHL M-Tronic (M) system ensures optimum engine performance, constant maximum speed and excellent acceleration. Manual carburetor adjustments are not necessary. |

|

The exact chain oil output can be adjusted manually for varying conditions, allowing for a reduction of up to 50%. |

|

The decompression valve is part of the easy starting system. The valve should be pressed before starting to reduce the compression pressure when starting, as well as the effort needed to pull the starter rope. The decompression valve is semi-automatic; it must be pressed manually before starting, but then closes automatically. |

|

Due to compression pressure, jerky stresses occur when starting internal combustion engines. The damping element in the ElastoStart special starter grip alternately absorbs and releases force according to the compression pattern. The result is smooth, even starting. |

|

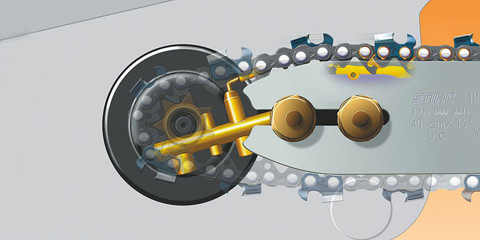

The tensioning screw can be found on the side of chain saw through the sprocket cover. This removes the need for contact with the sharp saw chain. |

|

Special caps to open and close the tank cap quickly, easily and without tools. |

|

STIHL long-life air filtration systems with pre-separation achieve perceptibly longer filter life compared with conventional filter systems. Air drawn in is swirled. The larger, heavier particles are ejected. The pre-cleaned air is routed to the air filter via the pre-separator duct. |

|

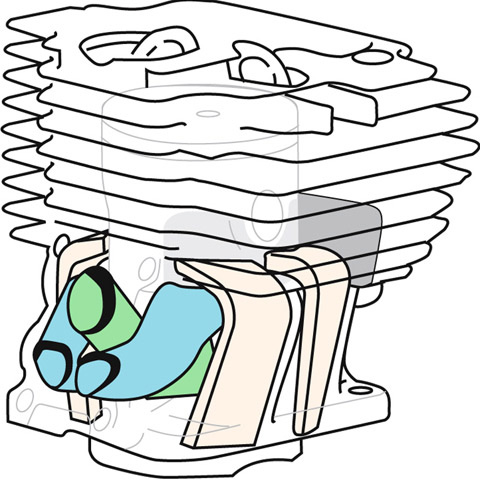

Four overflow channels swirl the fuel-air mix before ignition, allowing for optimum combustion and highly efficient performance. The result is lower fuel consumption and high torque across a broad rpm range. |

|

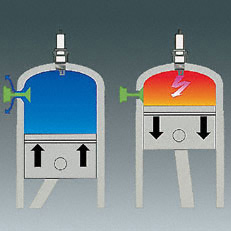

2-stroke engine with stratified charge. A fuel-free layer of air is created between the burned charge in the combustion chamber and the fresh charge in the crankcase, reducing the amount of fuel lost during the charge cycle. This results in more power with a lower weight, up to 20% lower fuel consumption than regular 2-stroke engines and significantly reduced exhaust emissions. |

|

By changing the chain saw from summer to winter operation, the intake air is pre-heated over the engine fins. This ensures that the carburettor does not ice up and you can continue working in freezing temperatures. |

|

Compared to conventional bars without Ematic, the STIHL Ematic system reduces the consumption of chain lubricant by up to 50 %, depending on the type of wood and the cutting attachment used. This system comprises a STIHL Ematic or Ematic S guide bar, a STIHL Oilomatic saw chain and a variable-flow or reduced-flow oil pump. As a result, virtually every drop of chain lubricant is delivered to exactly the right spot. |

|

Precisely calculated buffer zones minimise the transfer of engine and saw chain vibrations to the front and rear handles. The chainsaw therefore runs noticeably smoother. This allows the user to save their strength and work longer. |

STIHL M-Tronic (FT)

STIHL M-Tronic (FT) Controlled-delivery oil pump

Controlled-delivery oil pump Decompression valve

Decompression valve STIHL ElastoStart

STIHL ElastoStart Side-mounted chain tensioning

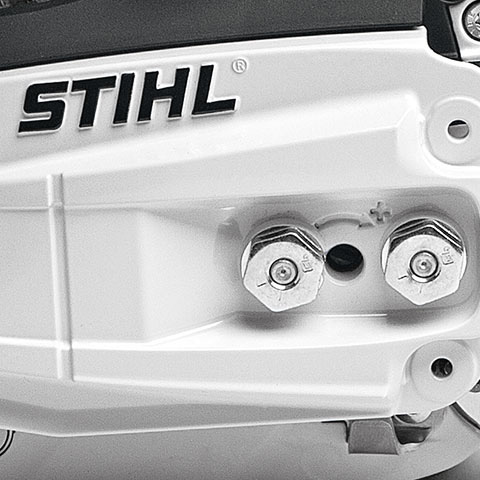

Side-mounted chain tensioning Tool free fuel caps

Tool free fuel caps Pre-separation air filtration system

Pre-separation air filtration system Advanced combustion technology

Advanced combustion technology Reduced-emission engine technology

Reduced-emission engine technology Heated carburetor (V)

Heated carburetor (V) STIHL Ematic System

STIHL Ematic System STIHL anti-vibration system

STIHL anti-vibration system