Fisher TEMPEST™ COMPACT STAINLESS STEEL HOPPER SPREADERS S035C* / S035A*

|

THE COMPACT CHOICE

The all-new HELIXX™ shaftless auger is best for precise rock salt application or the pintle chain conveyor is perfect for dense, heavy de-icing materials. Choose the material delivery system that best fits your operation and continue clearing the way for Fisher Nation. |

|

* Auger Models Only (S035A & S070A) |

|

PINTLE CHAIN CONVEYOR

* Chain Models Only (S035C & S070C) |

|

|

|

EXTENDED MATERIAL DELIVERY & PRE-WET CHAMBER

When equipped with the optional pre-wet accessory (S070C/S070A Models Only), it leads into the patented pre-wet mixing chamber. |

|

|

|

|

|

The ergonomic, hinged design allows the chute to flip up, providing easy access for maintenance or material unloading. For convenient access to the hitch, the chute assembly can be removed. |

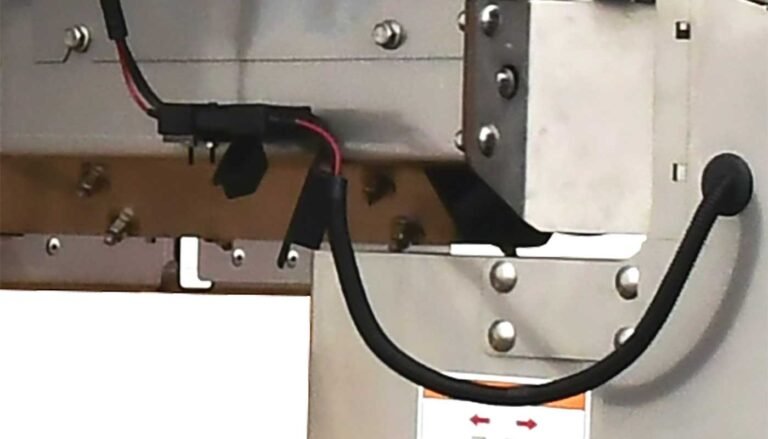

CHUTE POWER PLUG

CHUTE POWER PLUG

Heavy-duty, weather resistant plug is IP-68 rated. Positive latching ensures a secure connection, even with vibrations caused by consistent travel. The plug has been tested to 5,000 mating cycles for durability for many winter seasons to come. |

SPINNER CHANNELS & SPREAD PATTERN

SPINNER CHANNELS & SPREAD PATTERN

A 12″ polyurethane spinner delivers a broadcast spread pattern of up to 30 feet and provides long-lasting, corrosion-free performance. The ridges on the spinner ensure an even distribution of material throughout the spread arc. |

|

*Chain Models Only (S035C & S070C) |

TOP SCREEN

TOP SCREEN

A steel top screen comes standard, which helps break up large chunks of de-icing material during the loading process to prevent clogging and bridging during spreader operation. |

|

Easy-to-understand, digital self-diagnostics alert the operator when the spreader is empty or when adjustments are needed, and LEDs make the control easy to read. Its compact size compared to traditional controls fits easily into today’s modern truck cab designs. |

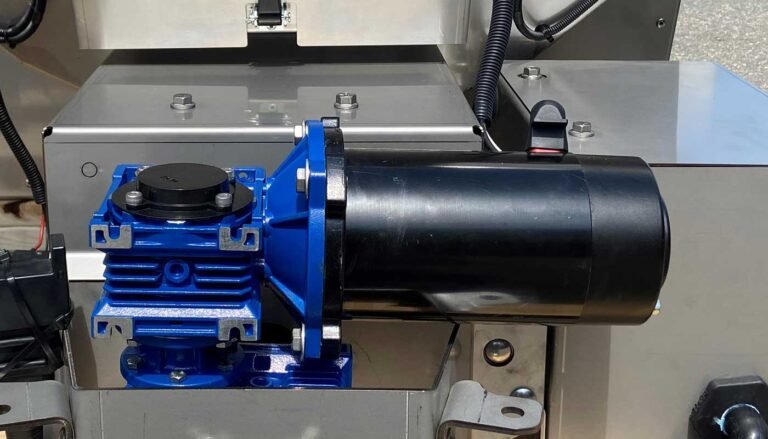

ELECTRIC MOTOR

ELECTRIC MOTOR

The two high-torque 12-volt electric motors provide quiet, reliable and independent control over the conveyor and spinner mechanisms. The spinner motor is sealed inside a weather-resistant housing, protecting it from corrosion, while the conveyor motor is completely sealed from the elements. |

SHUTTER DEFLECTOR

SHUTTER DEFLECTOR

The easy-to-adjust circular shutter deflector allows directional spreading, providing optimal material control, while maintaining even coverage. For quick adjustments, simply move the convenient hand operated lever. |

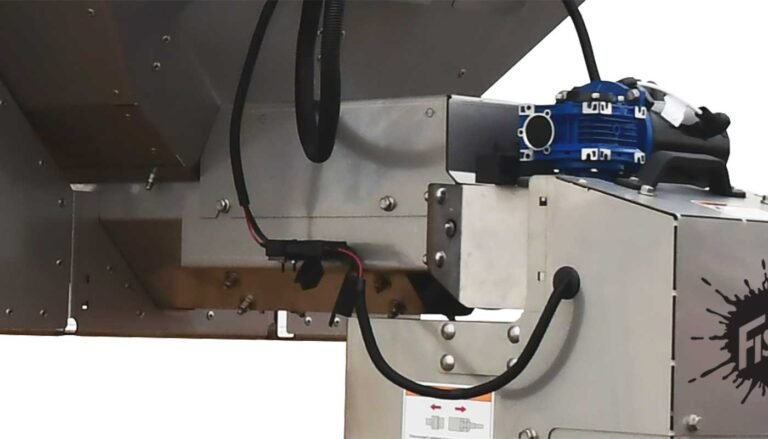

ACCESSORY INTEGRATION & KNOCK OUTS

ACCESSORY INTEGRATION & KNOCK OUTS

Conveniently connect accessories directly into the hub mounted in the back of the hopper. Accessories automatically integrate with the hopper control without having to run additional wires from the front of the truck. Hoppers feature knock-out holes for plug and play integration of certain accessories. |

DUMP & WORK LIGHT SWITCHES

DUMP & WORK LIGHT SWITCHES

Operators can safely offload material or fill walk-behind spreaders by using the rear mounted dump switches. A third switch is also provided so that an accessory work light may be conveniently controlled from not only the cab but also the rear of the hopper. |

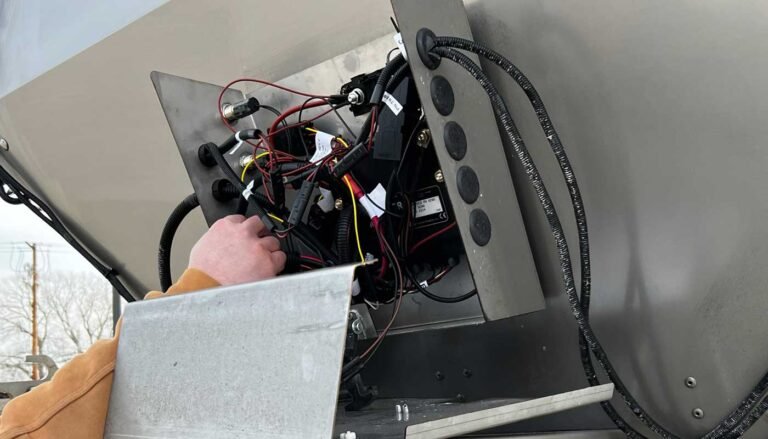

FLEET FLEX ELECTRICAL SYSTEM

FLEET FLEX ELECTRICAL SYSTEM

FISHER hopper spreaders are designed with FLEET FLEX technology for easy interchangeability between electric hopper spreaders without having to change the wiring or the controls. It provides easy operation, increased reliability, simple wiring and easy installation. Additionally, accessories automatically integrate into the control for easy plug and play. |

| SELL SHEETS | Download |

MATERIAL SPILL PROTECTOR (CHAIN ONLY)

MATERIAL SPILL PROTECTOR (CHAIN ONLY)

CONTROL

CONTROL